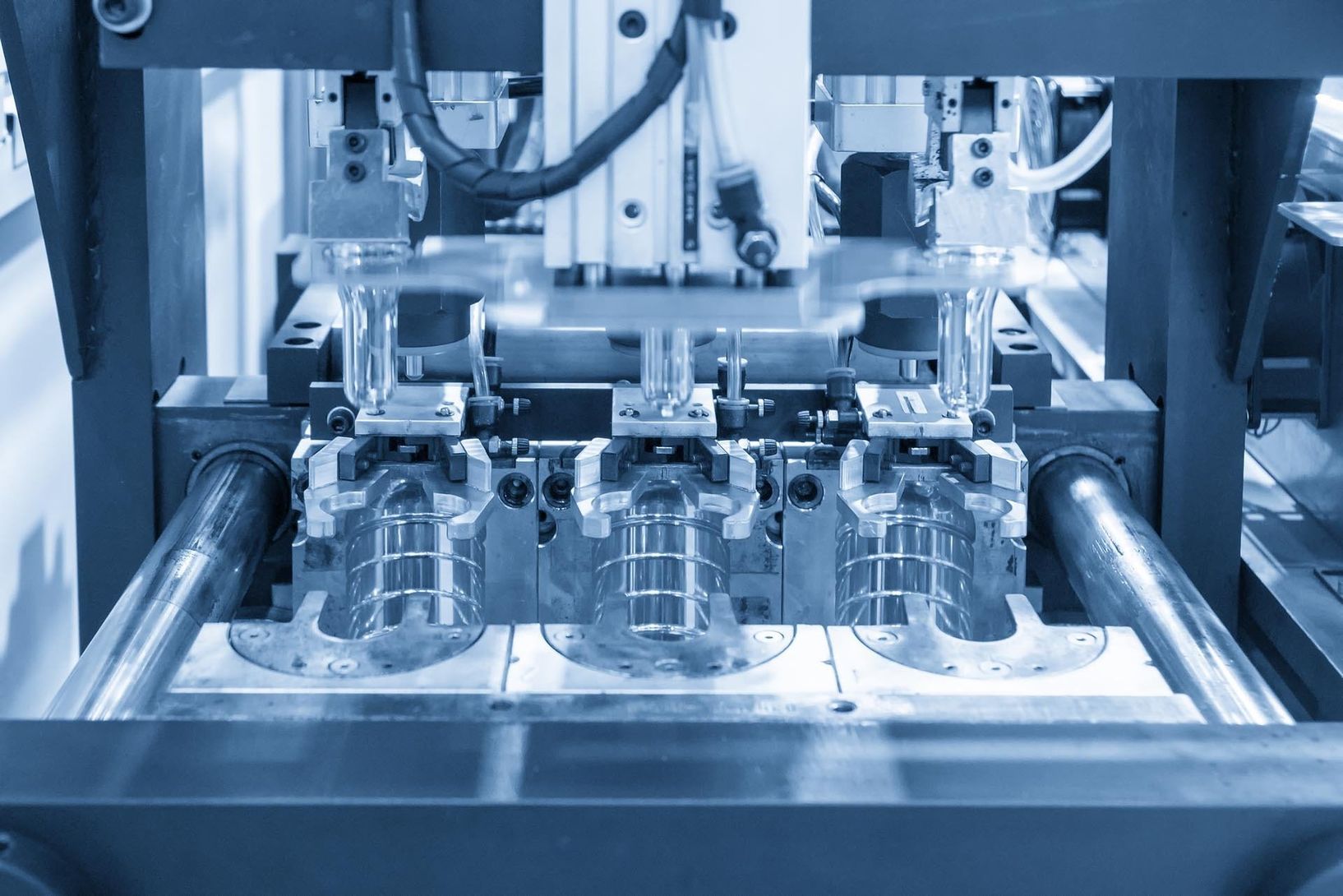

Extrusion Blow Moulds: Tailor-Made Solutions for Hollow Containers

Among M.D.C.’s core specialisations is the design and manufacture of extrusion blow moulds (EBM), serving clients across Italy and internationally.

This production technology allows for the creation of hollow plastic components such as:

• Bottles

• Flasks

• Tubes

• Jars and technical containers

How Blow Moulding Works

The process involves injecting compressed air into a preheated plastic parison, which is placed inside a hollow mould. The air expands the plastic, pressing it against the inner walls of the mould to perfectly replicate its shape.

After controlled cooling, the mould opens and the finished part is extracted, ready for any subsequent processing.

Thanks to state-of-the-art systems and highly specialised in-house expertise, M.D.C. produces blow moulds that are precise, durable, and fully customised to meet the client’s production needs.

Contact us to request more information or a free quote for the production of extrusion blow moulds.

Our Working Method: Tailor-Made Blow Moulds in Monza

For nearly 50 years, our Ronco Briantino facility has been active in the design and production of extrusion blow moulds (EBM), becoming a trusted partner for Italian and international companies in the cosmetics, pharmaceutical, and technical sectors.

Drawing on decades of experience, M.D.C. has developed advanced expertise in creating bespoke moulds, including:

• Hardened steel moulds

• Multi-cavity moulds

• Ideal solutions for

medium- to large-scale production, offering

efficiency and long-term durability

Our technical office supports clients from the earliest development stages:

• We assist in the

design of the products to be moulded

• We optimise geometries to ensure full

compatibility with extrusion blow moulding technology

• We assess

feasibility, materials, and production cycles

In addition, we offer a timely and professional after-sales support service, ensuring ongoing technical assistance for mould maintenance and optimisation over time.

Contact us for more information or to request a dedicated technical consultation.

Need a custom mould?

Request a personalised quote

for blow moulds: our technical team is here to help.