Design and Production of Plastic Moulds in Ronco Briantino (MB)

Design and Production of Plastic Moulds in Ronco Briantino (MB)

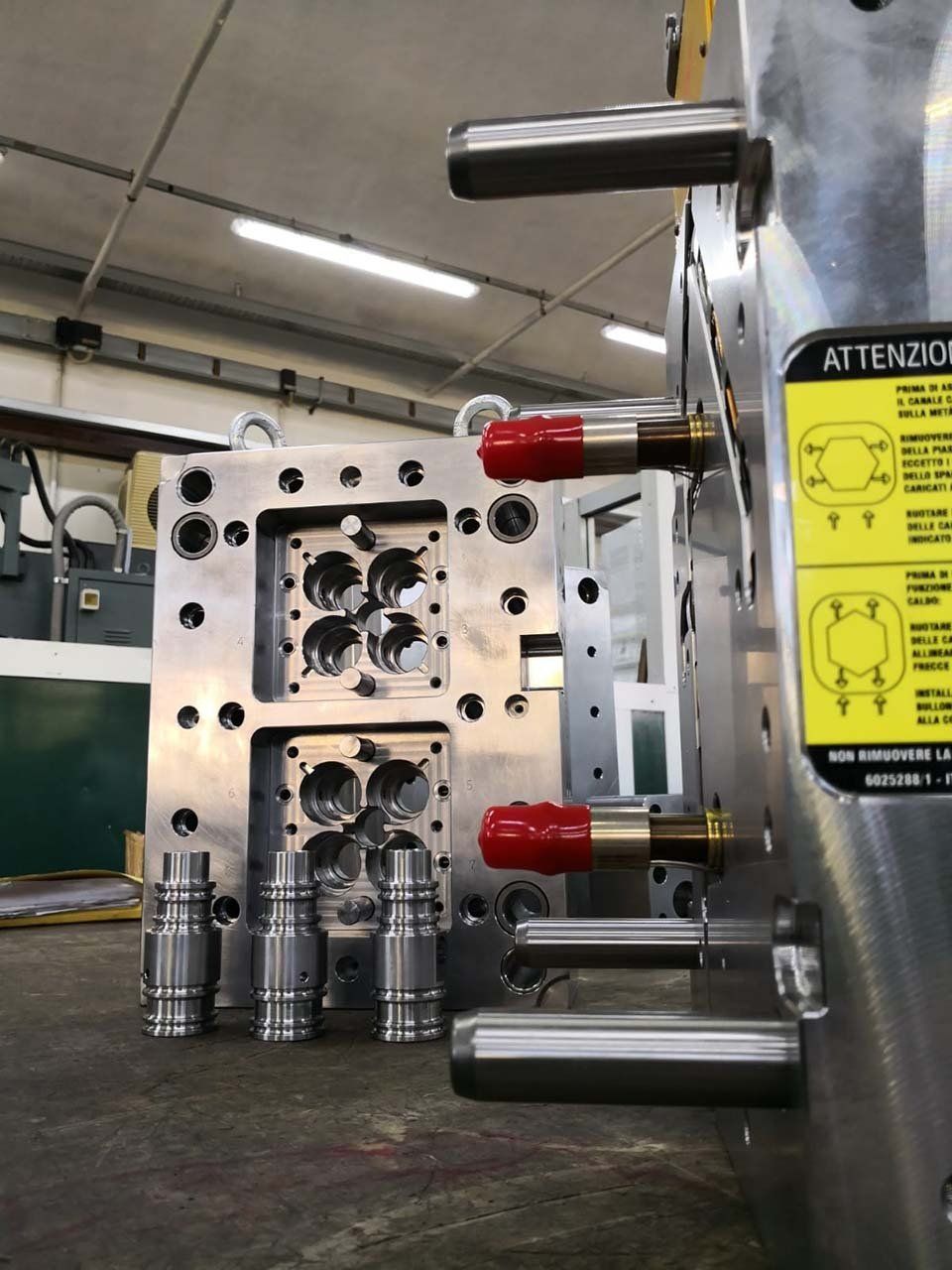

M.D.C. is a company specialising in the design and production of plastic moulds, operating nationwide and beyond.

Based in Ronco Briantino (MB), we offer businesses decades of experience combined with advanced processing technologies, enabling us to manufacture high-precision polymer components.

Types of Moulds Produced

We manufacture moulds for thermoplastic polymers using three main technologies:

• Injection moulds

• Injection blow moulds (IBM)

• Extrusion blow moulds (EBM)

Injection Moulding

This process involves melting the plastic material, which is then injected at high pressure into a closed mould. Once solidified, the piece is removed. This method ensures repeatability, precision, and high-quality finishes.

Extrusion Blow Moulding (EBM)

In this technology, a preheated plastic tube (parison) is inflated with compressed air inside a hollow mould, adhering to the walls until it cools. It is ideal for producing hollow items such as bottles or containers.

Injection Blow Moulding

In this case, the plastic material is first transformed into a preform, which is then transferred into a secondary mould and blown into its final shape. This process is ideal for applications requiring high-dimensional and aesthetic precision.

If you would like to learn more about how we

manufacture plastic moulds in Monza, or if you would like to request technical advice,

Get in touch with our team:

we’re here to provide all the information you need.

Injection Moulds for Plastics, also for Small to Medium Production Runs

For the production of injection moulds for plastic materials, M.D.C. relies on a technologically advanced workshop and a technical office specialised in research and development, capable of overseeing every stage of the project with care and expertise.

Thanks to this internal structure, we are able to offer tailored solutions even for small to medium production batches, with continuous control over quality and lead times.

Our core services include:

•

Development of technical product drawings

• Functional prototyping

• Selection of the most suitable technology (injection, injection blow, extrusion blow)

• Optimal cavity number sizing based on expected production volumes

• Pilot mould production

• Customisation of the mould to match the client’s equipment

We use only high-quality certified materials, with particular attention to heat treatments and surface coatings, to ensure strength, durability, and high performance.

Additionally, we offer comprehensive after-sales service, including both routine and extraordinary maintenance of moulds, to ensure continuity and reliability in our clients' production processes.

Contact us to receive more information or request a personalised quote.

Need a Custom Mould?

Request your personalised quote: our technical team is on hand to evaluate the best solution for your needs.